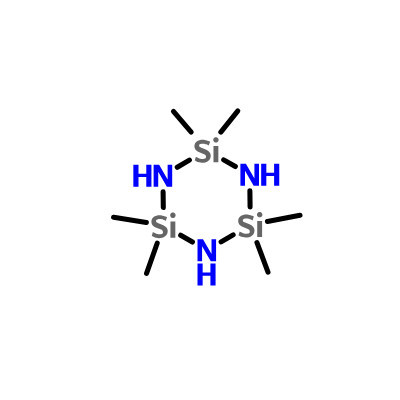

2,2,4,4,6,6-Hexamethylcyclotrisilazane CAS 1009-93-4

Category:

Product Description

Product Details

Introduction and Application

Hexamethylcyclotrisilazane is a liquid low molecular polymer with a main chain composed of Si-N bonds. It can be used to prepare high-purity silazane precursors with the expected degree of polymerization through ring-opening polymerization. It can be used in the photovoltaic industry and semiconductor industry for weather resistance and self-cleaning protection. The activity of Si-CH3 bonds is insufficient, and it is difficult to heat cure when used alone. Therefore, it is often used in combination with organic silazanes containing active groups, such as methyl hydrogen silazane to prepare Si-C-N ceramic fibers.

Si-N can react with hydroxyl-containing substances and can be used as an amine curing agent. It can also modify hydroxyl-containing resins to improve heat resistance and weather resistance, such as phenolic resins, epoxy resins, alkyd resins, acrylic resins, etc.

Silazanes are widely used in the rubber industry, ceramic industry, etc. For example, in the silicone rubber processing industry, silazanes are good additives. They can not only act as structure optimization control agents but also improve the heat resistance and mechanical strength of vulcanized rubber. Therefore, silazanes are added to other organic synthetic rubber processing industries to improve their thermal stability and mechanical strength.

Specification:

| Appearance | Colorless transparent liquid |

| Viscosity(s) | 11s |

| Content | ≥96% |

| Solid content | >98% |

| Density (g/mL) | 0.92±0.01 |

| Relative molecular weight | 218~221 |

| hardness | ≥2H |

| Adhesion | 0 class |

| Salt spray resistance | >500h |

| Temperature | 165℃ | 180℃ | 200℃ | 250℃ | |

| (Dry film 5-25 um, humidity 50%) | Surface Dryness | 1h | 0.2h | 0.1h | 0.1h |

| Actual drying | 1h | 1h | 0.5h | 0.5h | |

Package:

180kg/drum.

Store in a dry, cool, well-ventilated environment, away from heat and fire sources.

Keyword:

Send Inquiry

Leave a message immediately and receive free product consultation. We will arrange experts to contact you as soon as possible.