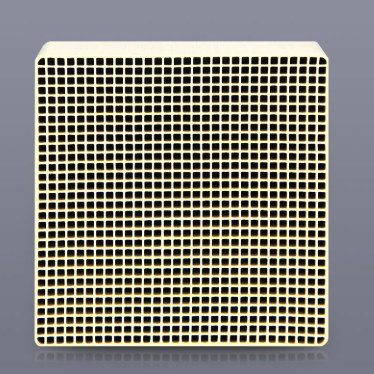

Coated SCR DeNOx Catalyst

Category:

Product Description

Product Details

Introduction

It has good hydrothermal stability, good sulfur resistance and good ability to resist HC poisoning, and can be integrated with the particulate filter (DPF);

The geometric surface area is large and the unit processing capacity is strong. Therefore, it occupies a small area and is especially suitable for the transformation and upgrading of existing projects;

The active temperature window is wide, which can be applied to low-temperature, medium-temperature and high-temperature flue gas denitrification to ensure sufficient denitrification rate;

The thermal expansion coefficient is low and can withstand frequent cold and hot starts;

The bed pressure loss is small, which greatly reduces the operating power consumption;

The overall structure is easy to install and replace.

Quality standard

| Item | Index |

| Honeycomb ceramic pore density | 100~400 pores/square inch |

| Thermal expansion coefficient | <1.5x10-6/C |

| Unit catalyst size | 150mm×150mm×150mm~200mm |

| Unit catalyst volume | 3.375~4.5L |

| Catalyst operating temperature | 300~550℃ 250~380℃ 180~350℃ |

| Operating air velocity | 20000hr-1~50000hr-1 |

Application

Coated SCR DeNOx Catalyst (coated selective catalytic reduction deNOx catalyst) is an industrial catalytic material used to control nitrogen oxide (NOx) emissions. It is mainly used in flue gas deNOx systems (such as thermal power plants, boilers, waste incineration, steel, cement and other industries).

Keyword:

Send Inquiry

Leave a message immediately and receive free product consultation. We will arrange experts to contact you as soon as possible.