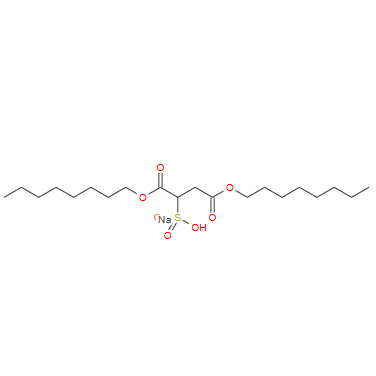

Sodium Diethylhexyl Sulfosuccinate CAS 1639-66-3

Category:

Product Description

Product Details

Introduction

Sodium Diethylhexyl Sulfosuccinate is an anionic surfactant with the characteristics of fast and uniform penetration, good wettability, emulsification and foaming properties. It is not resistant to strong acids, strong alkalis, heavy metal salts and reducing agents. It is soluble in hydrophilic solvents such as water and low-grade alcohols; it is also soluble in benzene, carbon tetrachloride, kerosene, petroleum series solvents, etc. The aqueous solution is milky white, and the pH value of 1% aqueous solution is 5.0-7.0. It penetrates quickly and evenly. The effect is better when the temperature is below 40°C and the pH value is between 5-10. Once silk fabrics are treated with penetrants, their penetration performance will not be affected by changes in temperature, acid and alkali, etc. It is mainly used for fabric penetration, printing and dyeing, pesticide emulsification, leather making, mineral processing, etc.

Quality standard

| Item | Index |

| Appearance | Colorless to yellow viscous liquid |

| Solid content/% | ≥50.0 |

| pH value (1% aqueous solution) | 5.0~7.0 |

| Osmotic pressure (1% aqueous solution)/s | ≤5.0 |

Applicaton

1. Dyeing of raw cotton: For example, cotton yarn is heated from room temperature to 95℃ with a 2g/L solution of this product, treated for 20 minutes for dehydration, cooled, bleached, cleaned, dechlorinated, and treated with this product once in the above method after cleaning and dehydration, and then the raw material can be dyed.

2. Scouring and bleaching of raw cotton products: During scouring and bleaching, the raw cotton products can be treated with this product solution at 20℃ for 5 minutes, and then other agents are added, and the temperature is gradually raised to 80~90℃ within 20~30 minutes. Continue to treat for 45 minutes. At this time, if the cotton shell has been removed, it can be dyed. The dosage is generally 2~3g/L.

3. Scouring, bleaching and dyeing of raw cotton products. This method requires the selection of direct or reactive dyes that can withstand oxidants. The dyeing preparation only needs to add dyes in the scouring and bleaching of method 2, and the process operation method is the same.

4. Scouring of viscose products: Viscose products generally have low temperature strength and are not resistant to strong scouring. Adding this product to the scouring bath can shorten the time by 2 hours, thereby reducing the damage to the fiber strength.

5. Use of asbestos products: To produce foam asbestos, add water and asbestos to the pulping pool and then add this product, then fully stir and mix into a paste, then add it to the mold and heat and bake it in the drying room. The dosage of this product is 10-15% of the asbestos; the production of dust-free asbestos thread is the same as the production of foam asbestos. After pulping, add it to the drawing mold and spray it into strips. After being treated with the color fixing agent Y solution, it is solidified into asbestos strips with a certain tensile strength. After drying the water, it is processed into thread and cloth. The dosage of the penetrant is 15-20% of the asbestos.

6. Use in the leather industry: Soaking treatment of dry board leather. Generally, this product is mixed with JFC in equal proportions. Soak at 25-36℃ or strengthen certain mechanical action for treatment, the dosage is generally 0.5-1.0%; when added as leather filling, this product can be mixed with filling resin impregnating agent to reduce the surface tension of resin emulsion and increase permeability. The general dosage is about 10% of the filling resin.

Keyword:

Send Inquiry

Leave a message immediately and receive free product consultation. We will arrange experts to contact you as soon as possible.